A recent pilot using a specially outfitted SUV to sniff out leaks in the natural gas system in the Selkirk area came out firing on all cylinders.

Natural Gas Programs Coordinator Joe Waatainen said the three-week test project covered 6,000 customers and approximately 325 kilometres of natural gas distribution and high-pressure transmission lines.

“The results to date have been amazing,” Joe said. “The mobile leak detection system we used found leaks we can barely detect with our traditional leak equipment. I really didn’t expect to see such an improvement in what we’re currently doing.

Manitoba Hydro manages several programs that keep the province’s natural gas system operating safely and efficiently including annual monitoring of buried and above ground natural gas piping to identify any leaks in the system. The surveys rotate throughout southern Manitoba where natural gas is delivered to 296,138 natural gas customers. When an underground leak is detected, Manitoba Hydro’s gas operations personnel are notified to repair the problem.

The annual leak survey starts in the spring and typically goes until late fall and is performed by approved contractors. The annual survey ensures the integrity of the natural gas system, reducing the possibility of damage to property and the environment. The annual surveys also collect information on several other conditions that could damage the natural gas system such as encroaching structures, construction activities, erosion, missing or damaged warning signs, and overgrown vegetation.

Each year about one quarter of the natural gas system is surveyed, or approximately 75,000 services. The survey also includes a complete inspection of the transmission system. Other annual surveys include inspections to monitor pipeline integrity in Winnipeg and city properties where the natural gas distribution system is covered by pavement. As a regulated natural gas provider, by law Manitoba Hydro must conduct annual surveys.

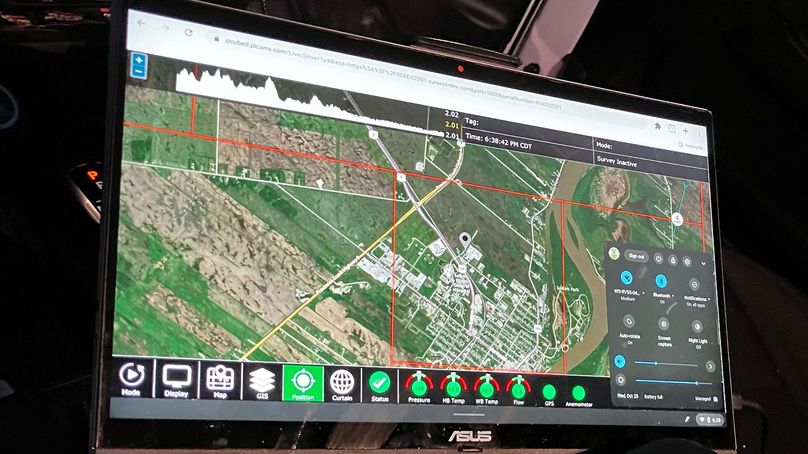

Diagram of the modified SUV.

These surveys have traditionally been done by field technicians during daylight hours walking along natural gas lines and up to gas meters attached to homes and commercial buildings.

Joe said besides detecting more leaks, mobile monitoring is less intrusive to customers as no one needs to go on to their property, and it can be done at night when customers are sleeping. A leak survey contractor will only have to enter a property now if a leak is detected and further investigation is required.

“It can transform the way we’ve done this work in the past and how we report on it,” Joe said. “We can also increase our rotation of how often we inspect the natural gas system which improves safety to our customers.”

“The mobile survey was done at the posted speed limit,” he said. “When a leak was detected, it was surveyed on foot the following day.”

The advanced mobile leak detection was recently demonstrated for other Manitoba Hydro employees.

“We successfully demonstrated the incredible sensitivity of the system and how the on-board computer using AI technology identified a leak that was only reading 4,000 PPM which is very small,” Joe said. “The traditional walking method struggled to find this leak, but the mobile system picked it up every pass at the posted speed limit.

How does it work?

-

Vehicle-mounted laser sensors use tunable diode lasers absorption spectroscopy with resolution in parts per billion, tuned for methane and ethane, allowing the vehicle’s on-board gas analyzer tell the difference between pipeline gas, which has ethane in it, and sewer gas. Because it can see in parts per billion, mobile monitoring can detect potential gas leaks from the road up to houses on both sides of a street.

-

Traditional walking surveys is more time-consuming and covers less ground. Technicians use a hand-held device to detect a gas leak.