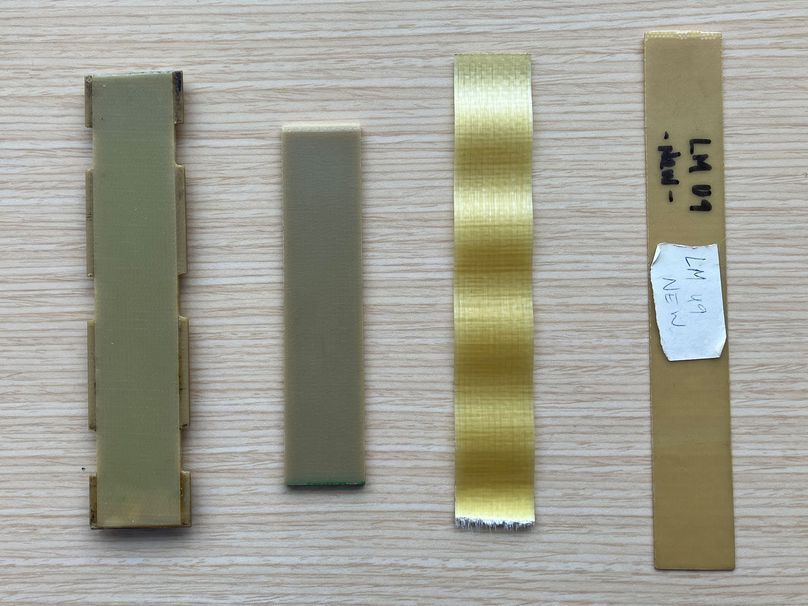

Our dams aren’t held together with sticks of gum, but something as small as a stick of Juicy Fruit can play a huge role in maintaining hundreds of millions of dollars’ worth of equipment.

These plastic wedges are like springs, they keep everything tight while the generating unit spins.

Around two inches long and called wedges, these little pieces of plastic go a long way toward preventing catastrophic damage to our generating station equipment.

“When generating units are spinning to generate power, these wedges add some compression,” said Marc de Rocquigny, a team leader in our generation projects department. “These wedges are like little springs, and as the unit expands and contracts, they cushion some of the motion and help keep everything tight while it’s moving. Even a thousandth of an inch difference [in looseness] can cause serious damage when they’re spinning.”

Hundreds of these little plastic wedges hold the stator in place. Without them, the stator – a large cylinder that stays stationary while the rotor, the spinning part of the generator, rotates – would start to move and become damaged over time.

Damage to either the stator or the rotor can lead to catastrophic failure of the generating unit, which would require significant, expensive repairs that would take a long time to perform.

Workers install new wedges in a generating unit at Limestone Generating Station.

Enlarge image: Workers install new wedges in a generating unit at Limestone Generating Station.

“It’s not too often that we have these units fully apart and we can actually see everything,” de Rocquigny says. “To enable us to replace the wedges, we take [the rotor] apart and we move it into a service bay. When it’s in the service bay, we can then access everything [in the stator]. Even though they’re such large machines, they’re very precise and delicate in terms of how they operate.”

Limestone is Manitoba’s largest generating station, containing 10 generating units. Its generating capacity – 1,350 megawatts (MW) – accounts for around 20 per cent of the province’s hydroelectricity.

The overhauls each represent a $7.08 million investment in each generating unit. The work consists of minor repairs to the entire generating unit in addition to replacing all the wedges on the stator.

Generating unit rotor out of stator pocket.

As the project manager leading the overhauls, de Rocquigny has been coordinating crews as they replace other equipment in the unit, which ensures the units don’t catch fire or explode during operation. The workers involved have also been cleaning and thoroughly inspecting each unit, helping to ensure each unit is operating efficiently.

Doing this work now is critical to ensuring the equipment can stay in use longer without requiring more significant upgrades or unplanned repairs that could cost in the hundreds of millions of dollars down the road. This work also helps avoid lost revenue that would result from longer downtime required to replace damaged equipment.

“These overhauls are like changing the oil in your car. If you don’t change the oil, yeah, it’ll still run, but not as long as it should,” de Rocquigny says.

Almost everything at Limestone is original from construction 30 years ago. Replacing these wedges, or “changing the oil,” is just one part of what’s happening right now at Limestone Generating Station to preserve our equipment, ensuring the units can provide power to Manitobans for decades to come. Making sure stations like Limestone live a long and productive life makes the most of the investments Manitobans have made in our electricity system.

“Taking care of the assets we already have is an important part of how we’re working to secure our energy supply today and into the future,” de Rocquigny said.